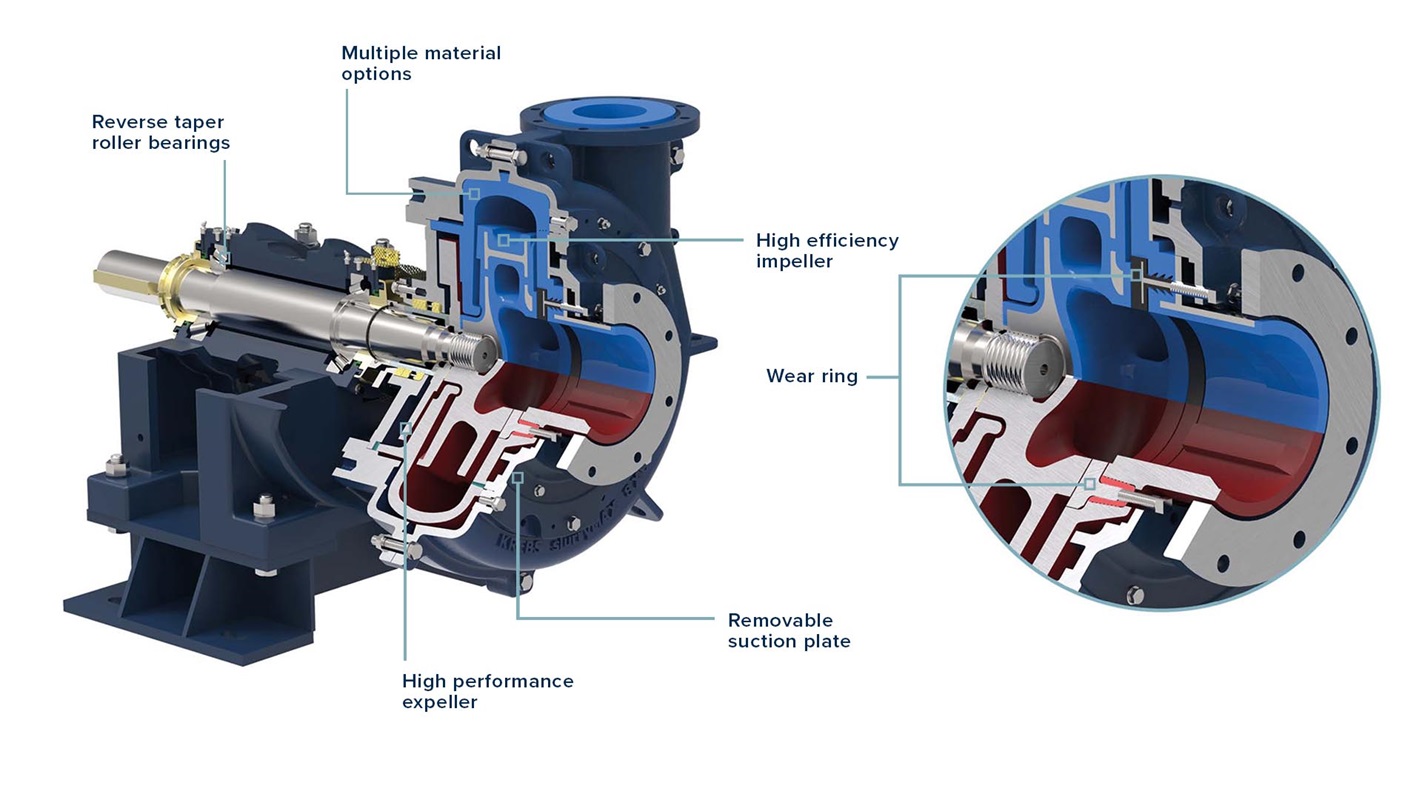

Multiple liner and impeller material options

Our slurryMAX handles the majority of applications for any plant across multiple industries. Simply put, the slurryMAX is the most versatile, efficient and longest-lasting slurry pump of its kind. Coupled with existing KREBS horizontal pumps, the slurryMAX will lower the total cost of ownership of every centrifugal slurry pump in your plant.

We think the safety of your fingers are ten great reasons to try a slurryMAX!

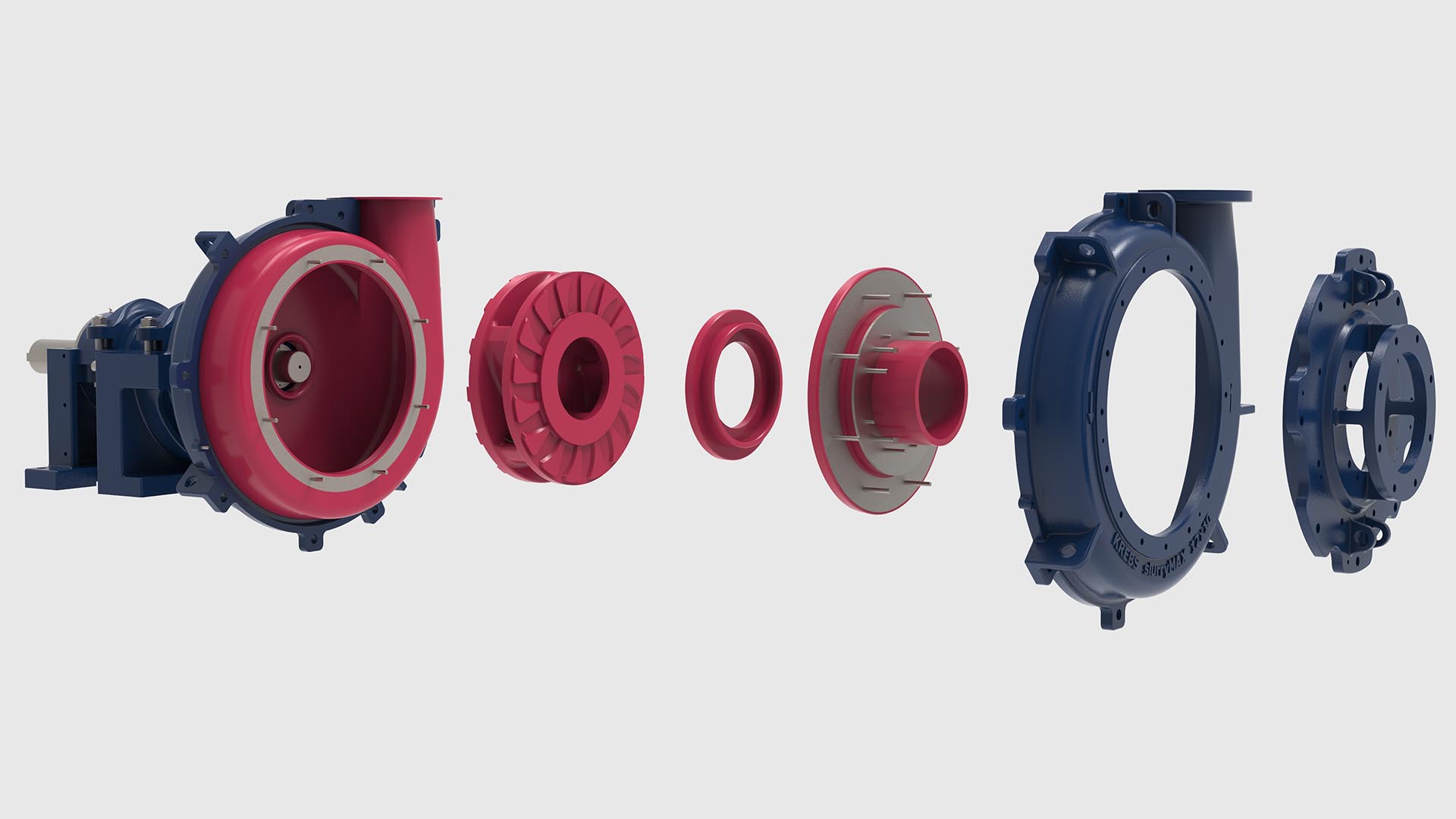

We designed a volute liner with an integrated back liner that bolts securely to the outer drive side casing for ease of assembly and hands-free safety. Our 8x6 and larger slurryMAX pumps feature a simple removable suction liner assembly for inspection of internals and replacement of impeller without removing the discharge pipe. Easy-to-use lifting jigs allows for safe and rapid rebuilds. Look to us for all your slurry pump needs, we aren't just the manufacturer, we design, provide solutions, monitoring technology and more. Check out our full line of horizontal slurry pumps.

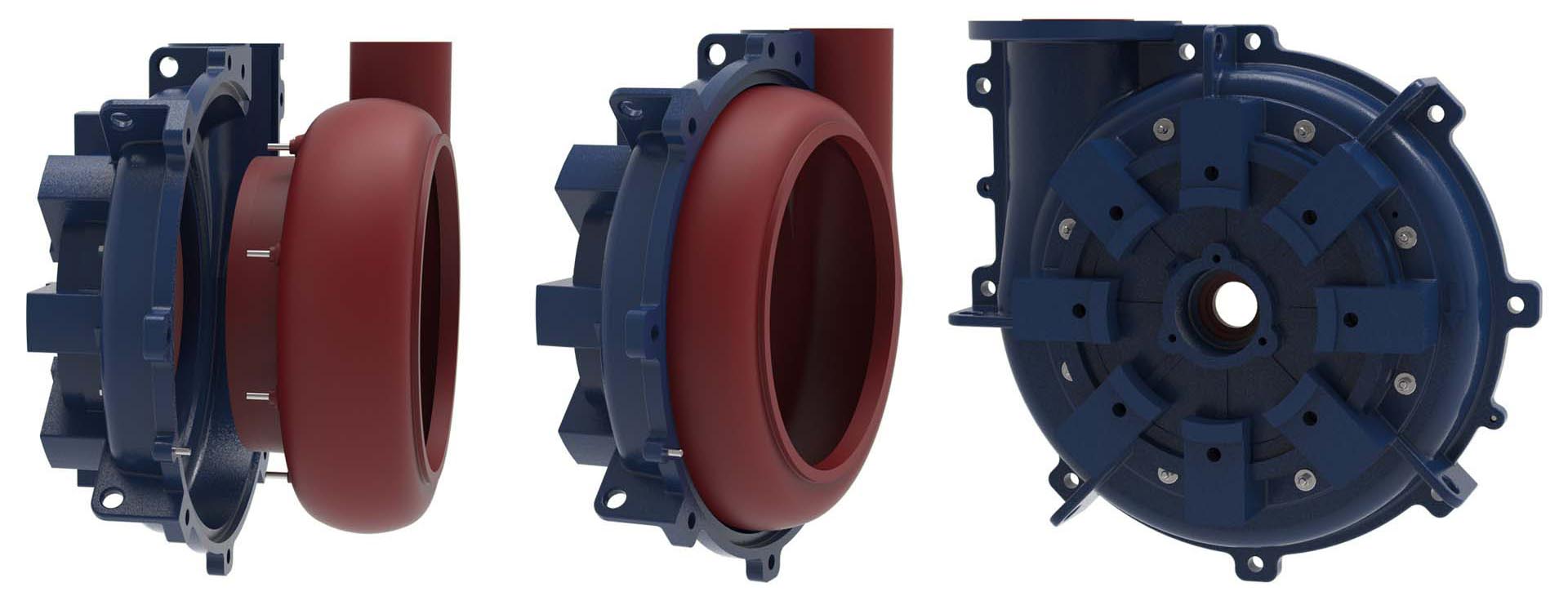

slurryMAX™-U with polyurethane liners, impellers and wear rings

The polyurethane liners in our new slurryMAX-U provide the perfect middle ground between traditional metal and elastomer lining in pumps. Our polyurethane liners thrive in fine particle applications where elastomers were once the only solution. They also give you the abrasion resistance of metal liners to protect against cutting and tearing due to sharp, large particle impact.

■ Cost effective

■ Excellent performance in fine particle applications

■ Higher impeller peripheral velocity limit

■ Corrosion resistance similar to rubber-lined pumps