In the aggregates industry, crushing to customer specifications is a must. For applications like asphalt and railway ballast in particular, meeting the correct particle size distribution and particle shape index is imperative. If your product doesn’t meet expectations, you risk expensive warranty claims and even lost business.

For years, this has been a situation that manufacturers have just had to deal with. But now the Raptor® cone crusher ‘50’ series has a solution in the form of advanced laser scanning.

Unprecedented real-time detail about the product coming out of your crusher

The advanced laser scanning system is integrated into all new RX50 cone crushers. It’s a 3D laser scanner coupled with advanced software that monitors and analyses your products as they leave the crusher.

This is a totally new development – not just for this range, but for the entire cone crusher market. The scanner provides unprecedented real-time detail about the product coming out of your crusher, including the particle size, capacity, and – uniquely – its shape. With this data you can determine how well your crusher is performing and any changes you need to make to operating parameters in order to achieve targeted performance. This puts you a step ahead of the competition and ensures you are delivering precisely what your customers want.

At last, you can analyse your crusher output in real time

Most people operate their crusher ‘blind’, hoping that the settings they are using will produce the product they want – but they won’t know for sure until thorough analysis has been carried out, by which point they may have already produced a lot of unsellable product. In particular, monitoring particle shape has – until now – been impossible, since conventional cameras can only provide 2D images of the crusher’s output. The laser scanner, however, gives 3D imaging and analysis. It’s a gamechanger, especially for the aggregates industry where shape often takes priority over size. Now, you can detect particle cubicity and determine whether it meets the required shape index.

Without this system, particles must be analysed in a laboratory, which takes a long time, leaving you with potentially hours’ worth of low-quality product. And with some industries making warranty claims against product that doesn’t meet the required shape index, it is evident that this new software will quickly prove its value.

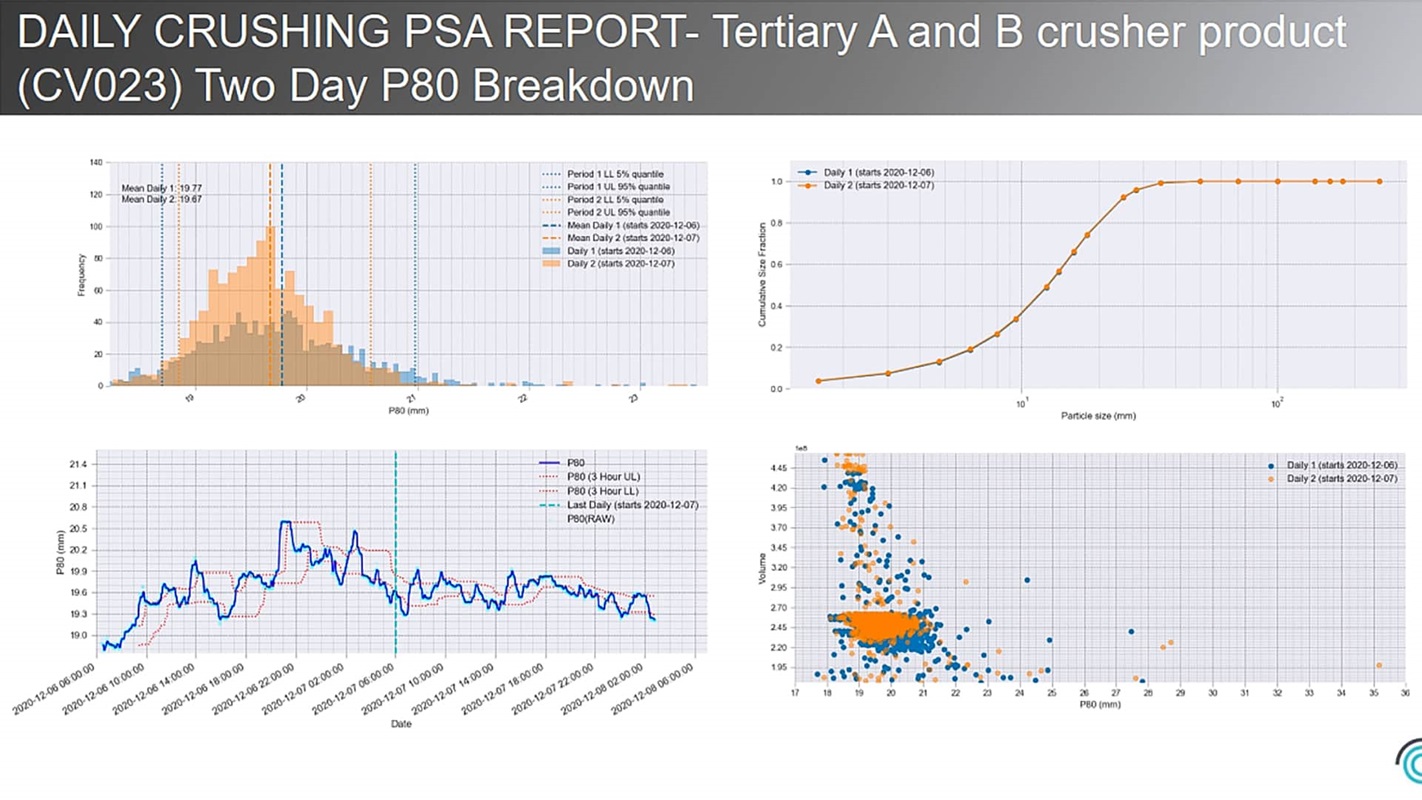

Daily crushing report - data gathered via the laser scanner helps you determine the optimum operating parameters