Dependable mill liners to boost your operation’s productivity

Productivity is paramount in your mining operation.

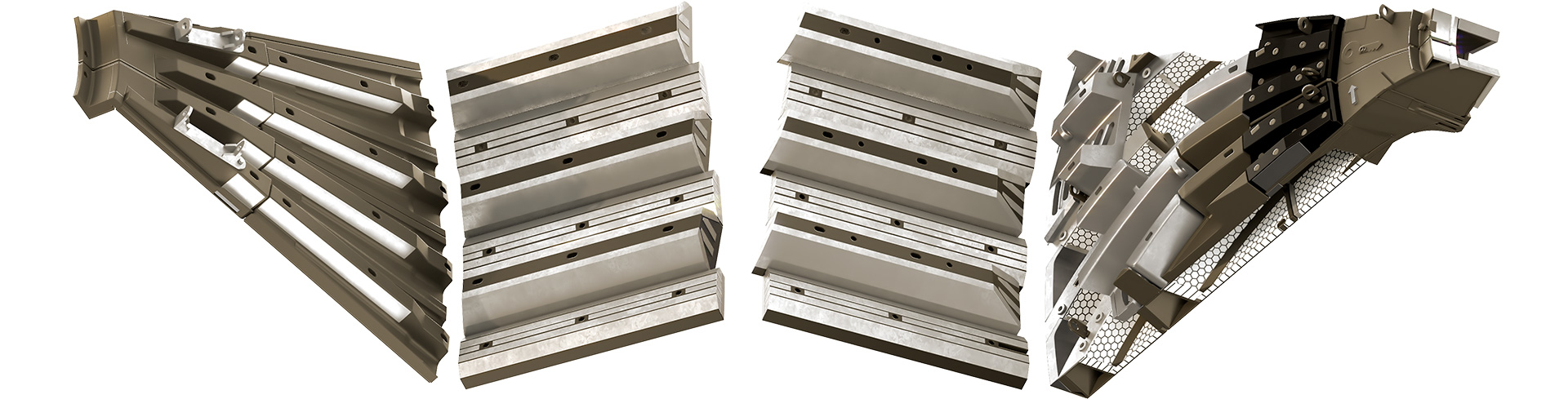

Mill liners fill a basic role: to protect your mills from the intense wear and tear that comes from grinding down hard, raw materials. But even if they all do the same job, not all mill liners are created equal. From the abrasion resistance of rubber to the impact resistance of steel, different material parts offer different advantages. FLSmidth supplies the full range of mill liners options, including composite, steel and rubber liner solutions.

Utilising new technologies, the designs of our mill liners are improved to increase safety and allow more accurate planning of their useful life. The material used in manufacturing the liners and lifters has been engineered to optimise operational conditions and in accordance with mineral characteristics.

We offer feedheads,shells, and discharge mill liners

Our engineers have created mill liner designs that:

Reduce the number of parts inside the mill

Reduce assembly and replacement time

Extend useful life of the parts

Increase grinding capacity

Optimise mill power use

Secure safe operation