Product Features

Treat the cause of pump wear, not the symptoms

The KREBS millMAX Pump’s unique design was developed exclusively for pumping abrasive slurries.

Prior to the millMAX, slurry pumps experienced two major problems: mechanical grinding of solids between the suction liner and impeller, and flow recirculating back to the impeller eye on the suction side. Both of these problems decrease pump life and increase power consumption. Conventional slurry pumps can only solve one of these issues through impeller and liner adjustment – but not both

millMAX™ Wear ring technology

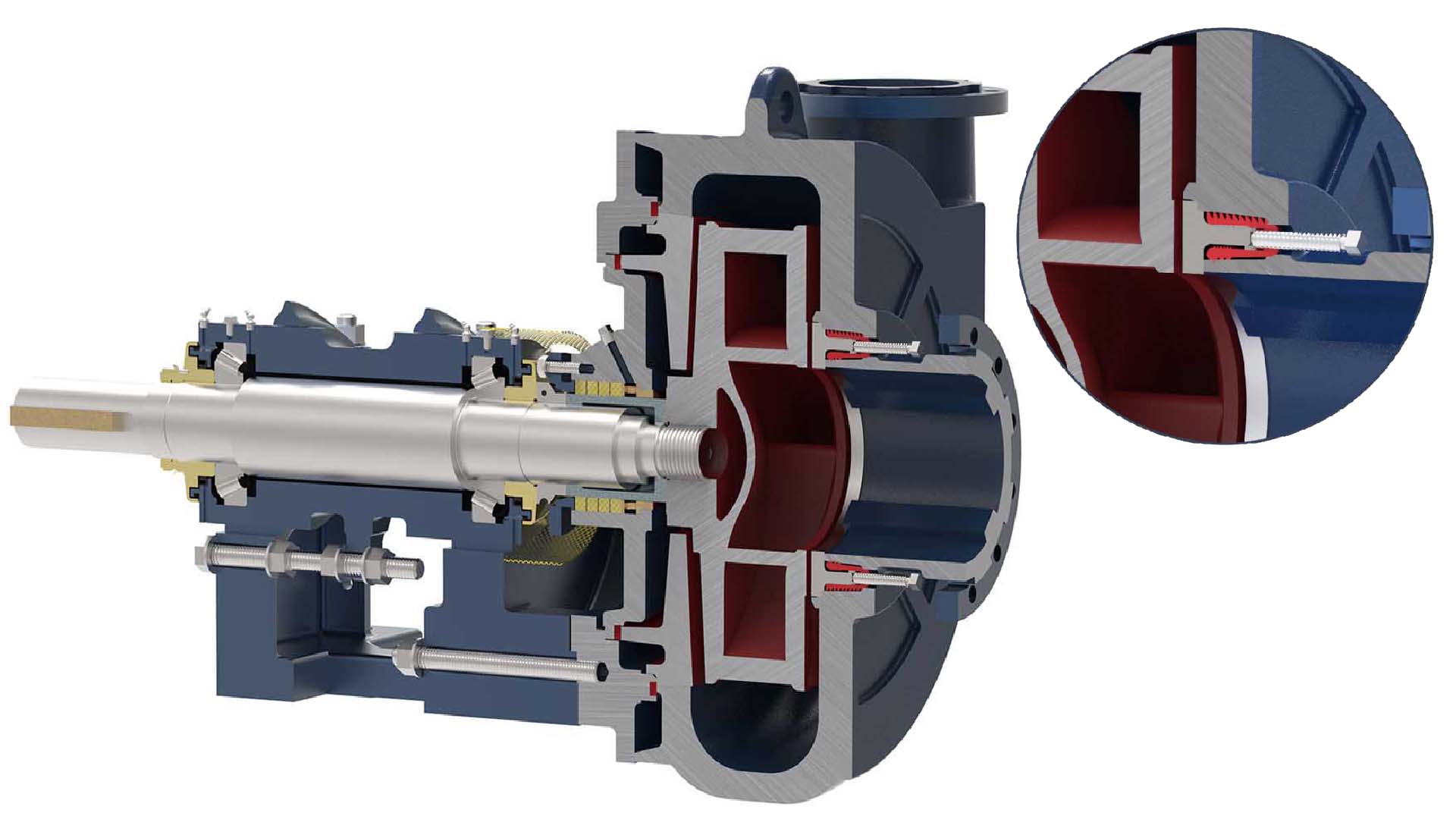

The image shows a closeup of wear ring assembly; wear ring, wear ring carrier and wear ring adjustment bolt. The millMAX™ product family features a proprietary suction-side sealing system, called the wear ring, that eliminates both major problems faced by conventional pumps. The wear ring closes the suction side gap while the pump is running restoring performance without speeding up the pump. This feature makes KREBS® pumps the only pump line that can effectively eliminate both the inefficient recirculation and the grinding of slurry.

High pressure pumps

High-pressure applications produce extreme forces on the pump suction liners, making full-face adjustment of traditional designs nearly impossible, as well as unsafe. The millMAX™ wear ring has a small cross-sectional area, and has proven to be easily adjustable in the highest-pressure applications.

The result? Our millMAX™ HP will easily maintain suction-side sealing throughout the life of the pump, leading to higher pumping efficiency and constant operating speeds for a given discharge head. These factors increase the wear life of the wet-end components over our competition.

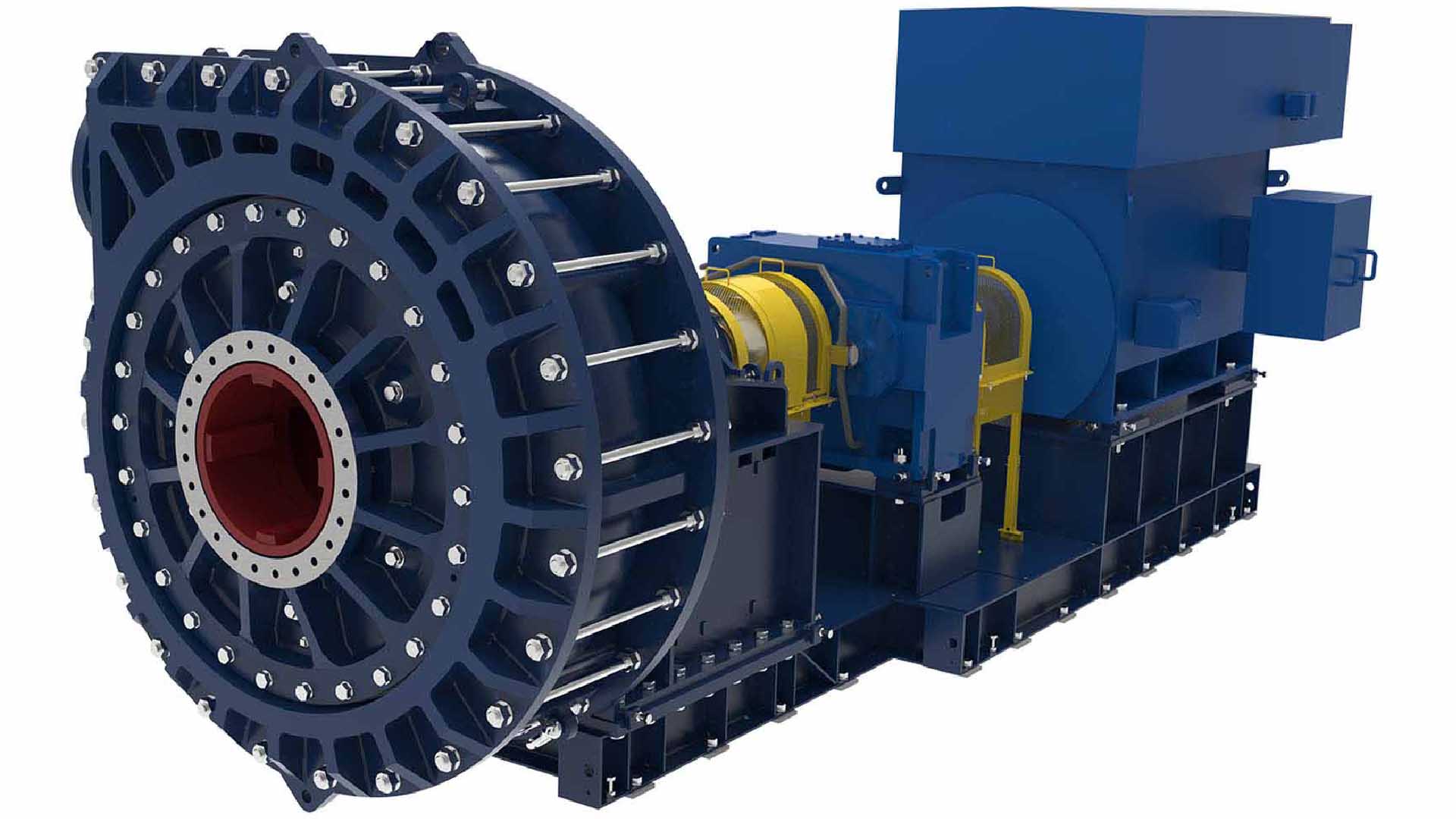

millMAX™ High-Head pump

Our millMAX™ High-Head (millMAX™ HH) Pump was designed for applications that have high total dynamic head requirements. Standard volute slurry pumps experience radial thrust on their impellers due to differential pressure zones within the pump casing when they operate far away from their best efficiency point (BEP). This radial thrust causes shaft deflection and premature bearing and gland-sealing failures.

The millMAX™ HH concentric casing design creates an even velocity and pressure around the casing. millMAX™ HH pump casings have higher pressure ratings to account for high-speed and multi-stage application.

SMART PUMPS - One simple app for better understanding and improving your operation

With the combination of our SiteConnect™ app and KREBS® Smart Pumps, you now have access to real-time information about your pumps on any phone or mobile device. Get instant alerts about operational deviations so that you know about potential problems before they occur. With better information about current operation, historical data, trends and advanced calculations, one simple app gives you a snapshot of the overall health of your entire plant. Learn more SiteConnect™ mobile app.