In a process plant, standby pumps often operate in critical areas. In many instances, two or more pumps discharge into a common line leading to the next step in the process. Prior to the development of the TT Valve, this junction required a shutoff valve on each pump discharge line to prevent the fluid from flowing back through the inoperative pump.

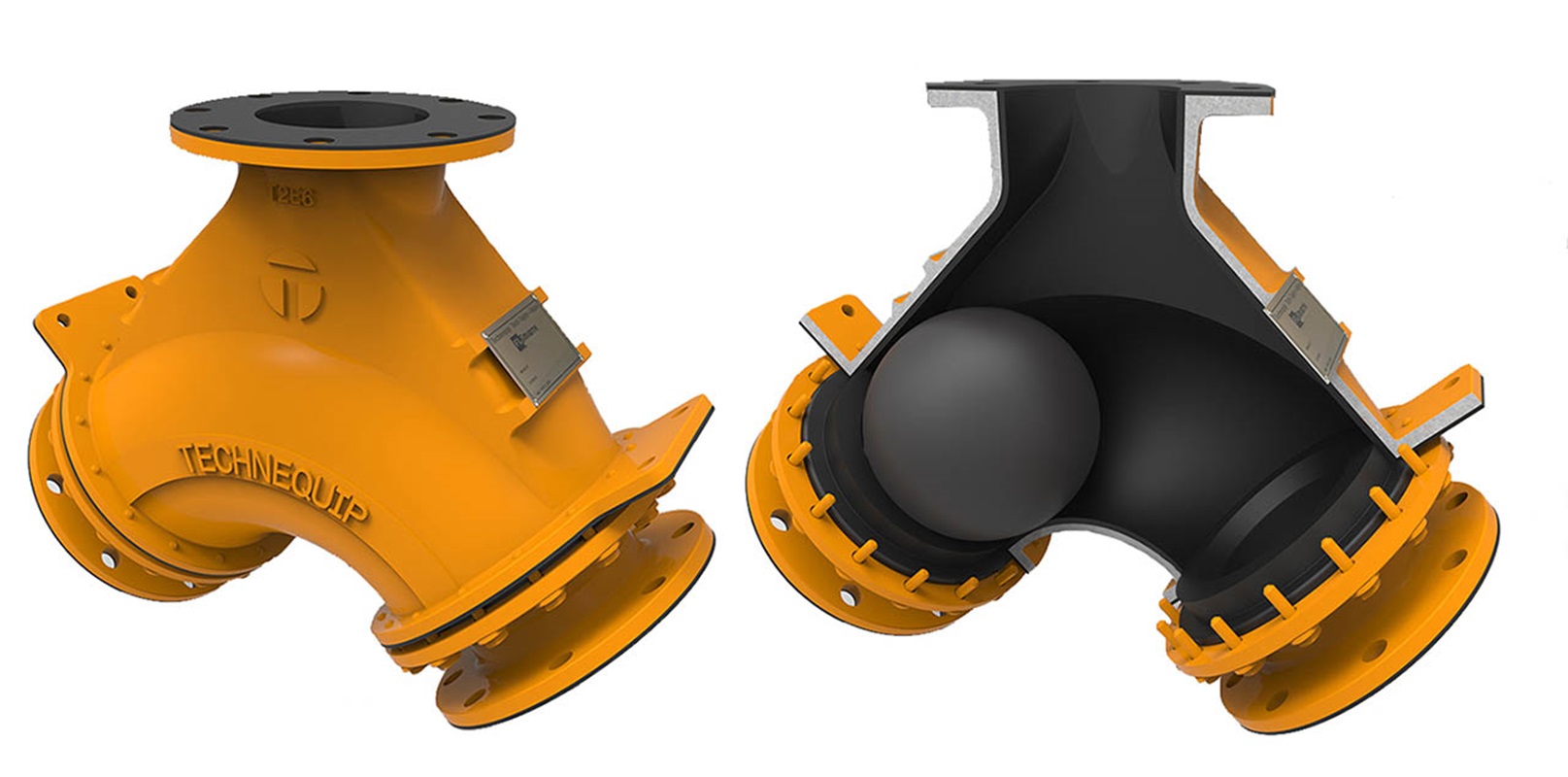

The Tech-Taylor Valve performs these functions automatically, operating in any position, without any external energy source. It prevents the need for multiple knife gate valves and expensive rubber-lined piping components. The body of the TT Valve replaces the “Y” fitting formerly required for standby pumps, and is designed for maximum abrasion resistance and minimal pressure drop – making it a trouble-free addition to your piping system.

Designed for installation in equipment where there are two pumps operating in parallel, it allows either of the pumps to work individually, as well as simultaneously during the changeover.

The TT Valve has been proven since the mid 1960s. It was invented by a mining professional, specifically for the mining industry. Today, there is hardly a mining facility in the world that has not had some experience with the Tech-Taylor valve. It simply is the best answer available for pump isolation.