Advanced LOW-STRESS Trommel design

Increase your milling productivity with our strong and LOW-STRESS modular design.

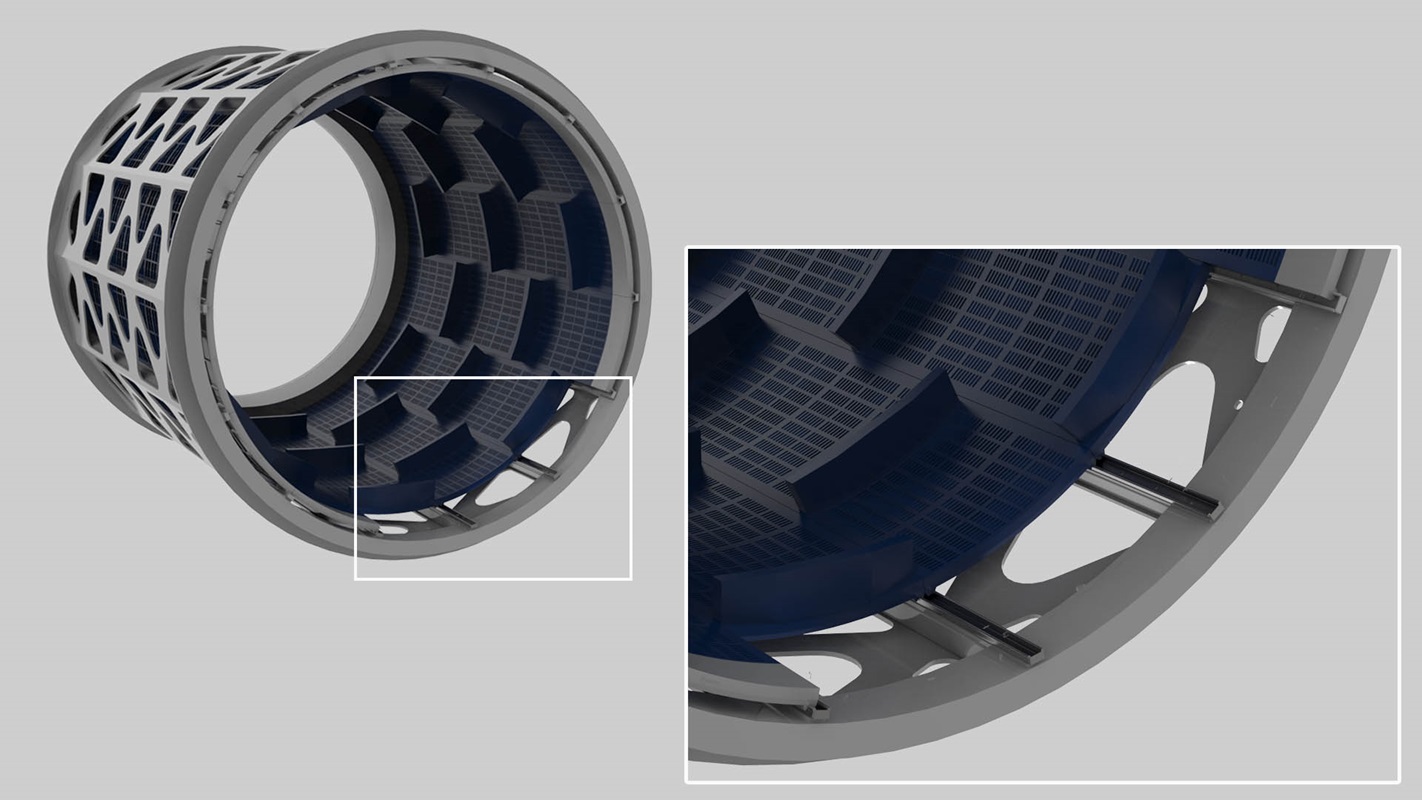

Advanced trommel design

All mines want to reduce unexpected events and downtime. With our trommel frames, you can rest assured that your equipment is of the highest quality – engineered to be strong and lightweight, and designed to increase your uptime and provide safe handling.

We manufacture our trommel frames and screen media in FLSmidth fabrication centres around the globe, according to internationally accepted engineering standards and procedures.

Strong and durable

To extend and maximise your asset life, we verify the structural design of our trommel frames through finite element analysis (FEA). This guarantees the engineering behind all components of the frames. Complete design using an FEA calculation includes static and fatigue/strength assessment, as well as strength assessment on the bolts.

We stress relieve your trommel frame after fabrication and before machining. We also apply protective lining on each frame in the areas that are likely to be exposed to erosive and abrasive wear.

Screening media size options

To ensure rapid delivery and streamline inventory management, our screening media is available in two standard sizes and in a number of thickness combinations. Our modular screen media panel sizes are 657 mm × 400 mm (25.86 in × 15.75 in) and 726 mm × 400 mm (26.75 in × 28.58 in). These standard dimensions allow us to supply your media from any FLSmidth manufacturing centre, and guarantee your media will conform to our unparalleled quality requirements and material specifications, while providing equal fabrication reproducibility.

Our experienced engineers are committed to finding the best solutions. We examine every aspect of your screening process to help ensure efficient pulp flow characteristics, proper separation, maximum wear life and maximum equipment uptime.

Pulp flow

We use our state-of-the art discrete element modeling (DEM) software to simulate your trommel performance. We then model, predict, optimise and enhance your assets for the highest possible recoveries and efficiencies.

Screening media configuration

Using DEM software, we analyse your trommel’s material distribution in order to optimise your screening media configuration.